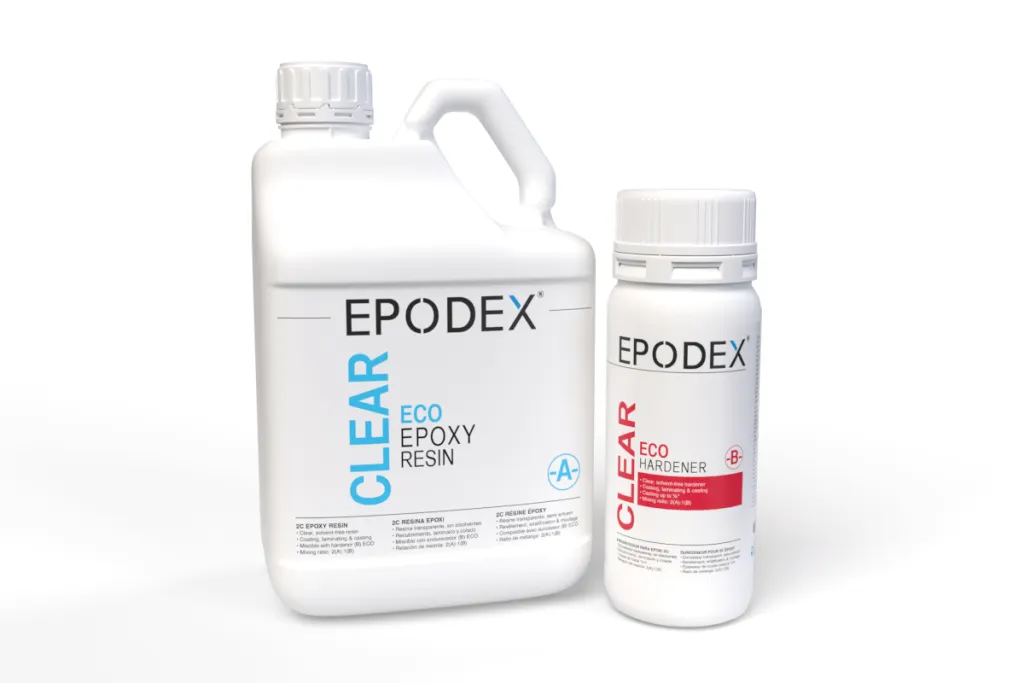

Epoxy Resin System for Stone Carpets (Resin + Hardener)

Epoxy resin for the production of stone carpets of all kinds.

1. Quantity of epoxy resin (Resin A + Hardener B)

EPODEX Epoxy Resin System for Stone Carpets (Resin + Hardener)

The ECO epoxy resin system is ideal for creating a stone carpet. Coat your floors, stairs, and other surfaces.

Instructions for use

- The scope of delivery includes resin (A) and hardener (B). Mix the contents of the resin (A) with the contents of the hardener (B) in a mixing ratio of 2:1 (e.g., 2kg resin: 1kg hardener).

- Pass the stir stick through the rim and bottom of the mixing container, as the material will settle there. Ideally, transfer the mixture to a clean container and mix again. This will ensure that the resin (A) and hardener (B) are completely mixed together.

- Then mix the resin-hardener mixture with your quartz stones. Add 4% of the resin-hardener mixture by weight to the quantity of quartz stones (e.g., 1kg of the resin-hardener to 25kg of quartz stones).

- Then spread the material on the desired surface.

- The material is touchable/walkable after 20 hours and fully chemically cured after about 7 days.

- For more information on our ECO system, please refer to the information table under the "Learn more" info button on this product page.

Epoxy resin is sensitive to any kind of moisture during curing (risk of carbamate formation, i.e. white patches in the top layer). For this reason, we recommend that you avoid any contact between water and the epoxy until it has cured completely (at least 7 days). For thin layers, cold temperatures (ambient, substrate, and resin temperatures below 20°C) and increased humidity, the time until the epoxy resin is fully cured may be extended.

Customer Service:

If you have further questions, please contact us by phone, e-mail or use our WhatsApp support. Note: Please note that due to different lighting conditions and monitors, the colours may not be uniformly displayed.

Ingredients, Security & Danger statements

Warning: 2,2'-[(1-methylethylidene)bis(4,1-phenyleneoxymethylene)]bisoxirane Reaction mass of 2,2’-[methylenebis(4,1-phenyleneoxymethylene)]dioxirane and [2-({2-[4-(oxiran-2-ylmethoxy)benzyl]phenoxy}methyl)oxirane and [2,2’-[methylenebis(2,1-phenyleneoxymethylene)]dioxirane Oxirane, mono((C12-14-alkyloxy)methyl)derivs Causes skin irritation Causes serious eye irritation May cause an allergic skin reaction Toxic to aquatic life with long lasting effects Avoid breathing dust/fume/gas/mist/vapours/spray. Avoid release to the environment. Wear protective gloves/eye protection/face protection. IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. If skin irritation or rash occurs: Get medical advice/attention. Dispose of contents/container to in accordance with local/regional/international regulations. Contains epoxy constituents. May produce an allergic reaction.

B-Components (ECO) Danger: Reaction products of 3-aminomethyl-3,5,5-trimethylcyclohexylamine and 4,4’-Isopropylidenediphenol, oligomeric reaction products with 1-chloro-2,3-epoxypropane m-phenylenebis(methylamine) Salicylic acid Causes severe skin burns and eye damage. May cause an allergic skin reaction Harmful to aquatic life with long lasting effects Do not breathe dust/fume/gas/mist/vapours/spray. Wear protective gloves/eye protection/face protection. IF ON SKIN (or hair): Take off immediately all contaminated clothing. Rinse skin with water [or shower]. IF INHALED: Remove person to fresh air and keep comfortable for breathing. Immediately call a POISON CENTER/doctor. IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. Specific treatment (see on this label). Take off contaminated clothing and wash it before reuse. Store locked up. Dispose of contents/container to in accordance with local/regional/international regulations.