Epoxy Resin Floor from EPODEX

Epoxy Resin Floor

High-quality epoxy resin from EPODEX to seal or coat your floors yourself. Our resin kits can be used to coat load-bearing floors like garage floors, kitchen, and living room floors, or industrial floors. It can be applied to a variety of surfaces, such as concrete, wood, plastics, or GRP to create a stable and impact-resistant floor coating.

Our wide range of colours allows you to dye the resin in your desired colour to set visual highlights on your floor.

- Can be used on all surfaces such as concrete, screed, wood and more

- Layer thickness: approx. 0,4-1,5mm

- Working time: approx. 120min.

- Curing time: approx. 24h

- Application instructions can be found on this product page

Unique Floor Coatings

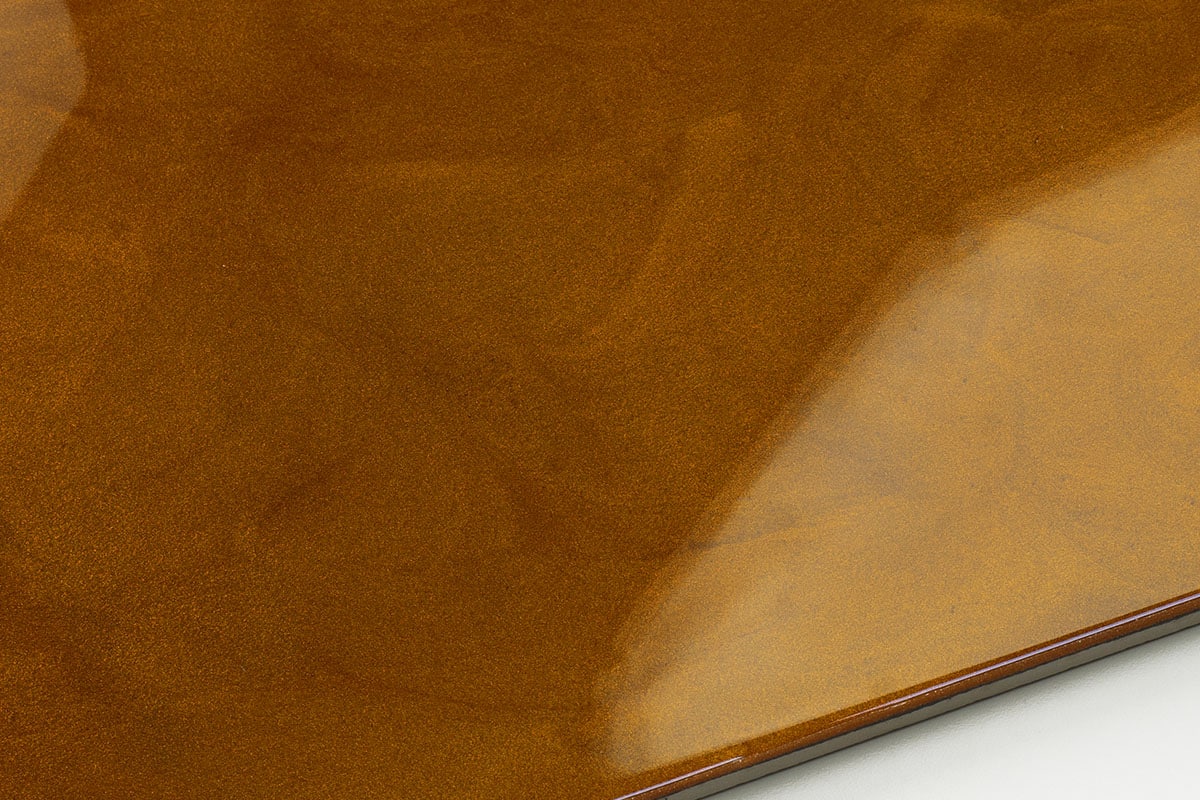

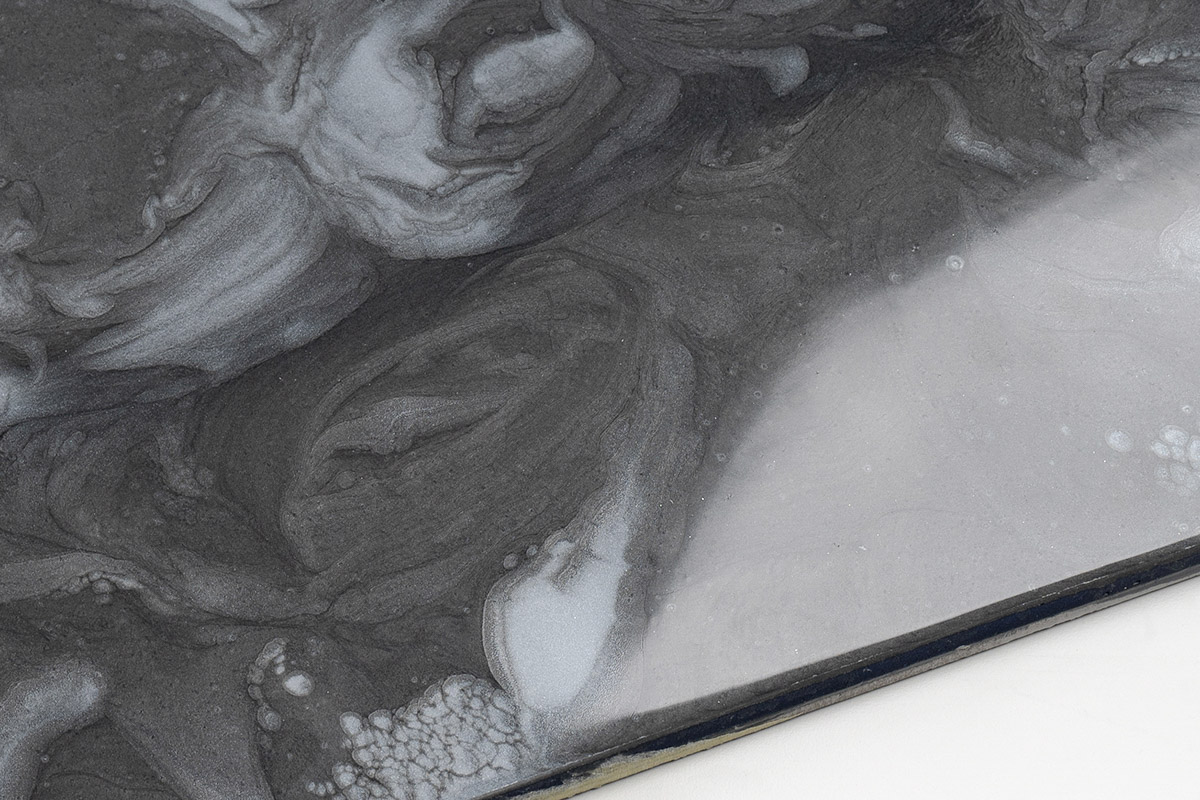

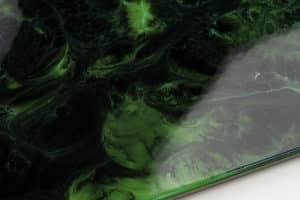

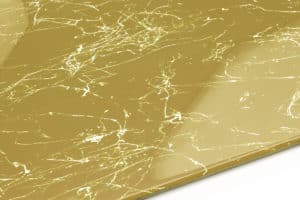

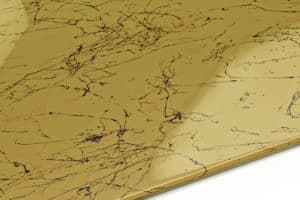

A resin floor coating protects your floor from material decay and moisture. It improves the overall look of your space. Use our metallic colours or flakes to create uniquely designed floors. You can easily cast marble floor patterns or implement extraordinary colour effects. In comparison to a genuine marble floor, this process will save you a ton of money!

EPODEX offers a wide range of colours for your epoxy resin floor. All our transparent colours, colour pastes, & colour pigments can be mixed in combination with each other allowing results in countless ways.

Do you have questions about our products?

Please contact our customer service team. You can reach us by phone, e-mail and WhatsApp.

More than

1000000+

Satisfied customers

How-To Guide

1. Clean and Mask the Surface

Make sure that the floor to be coated is not uneven and is free of any cracks, breaks, or holes. For a proper coating, make sure the floor is also free of weight-bearing items, is dry, and is dust-free. If these conditions are met mask the floor edges with tape to proceed. It is best to wear nail soles during the application process to avoid leaving marks on the surface. Wear a respirator mask and old clothes such as disposable overalls.

2. Prime the Surface

To cover all floor pores and reduce material loss, prime the floor with a thin epoxy layer of 0.2-0.3cm. Mix the required amount for the first thin layer and stir the two components together slowly and thoroughly for about 3 minutes. Then spread the resin on the floor with the paint roller. The best results are achieved when painting in a crosswise motion as this closes all the pores on the floor. Work quickly, observing the pot life. Allow the primer to cure completely before applying the main coating.

3. Apply the Main Coating

Once the primer has cured, start with the main coating. Our metallic colours are supplied as pigment powders in sachets. This allows you to determine how much colour pigment you want to mix into the epoxy resin, particularly when intending to use several metallic colours at once. Mix the resin and hardener in the correct ratio as you want to do for each metallic colour used. Then pour the metallic pigment into the mixing jug and mix the pigment with the crystal clear resin. Then cast the epoxy resin onto the primed floor, spread it with a paint roller or squeegee and repeat the process for the other metallic colours. We recommend a layer thickness of 1.5mm for the pre-coating. For garage or industrial floorings, add quartz sand or synthetic fibres, which increase the pressure- and tread resistance of your epoxy resin floor.

4. Remove the Masking Material

After processing, remove all tapes and enjoy your brand new glossy, seamless, epoxy resin floor. For optimal results, pay close attention to the room temperature and curing times.